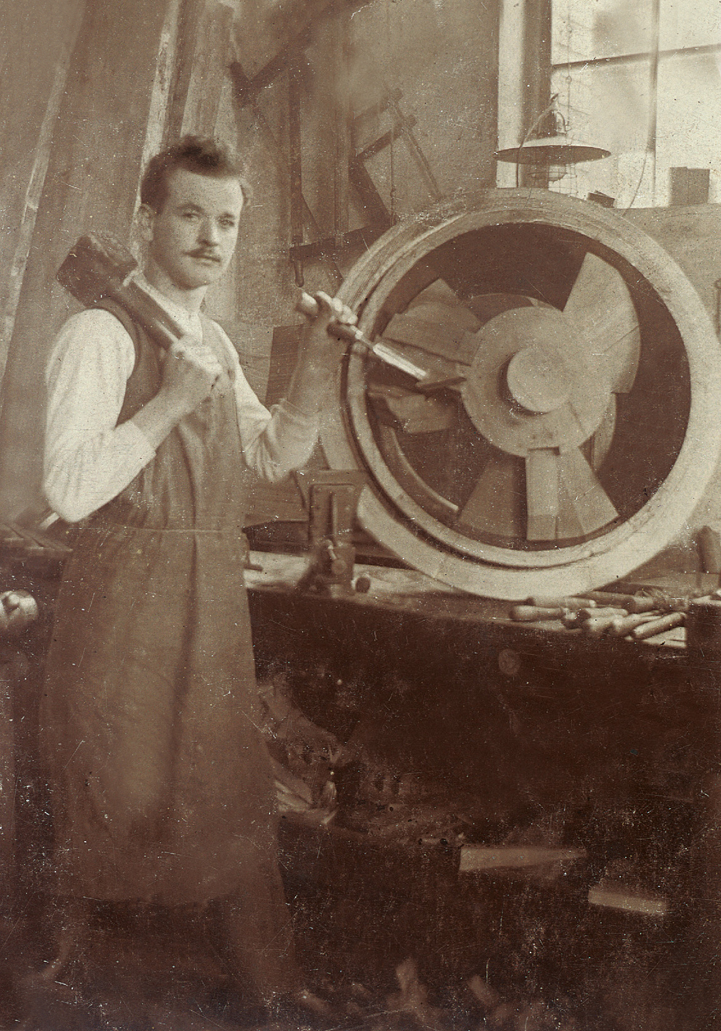

August Maus, Firmengründer

Having visions,

living visions,

sharing visions,

realising visions together….

Already the 4th generation, we run the business, founded by August Maus in 1925 for pattern making, with pride and commitment.

The latest trend-setting technologies, combined with tradition and the craftsmanship of “Made-in-Germany” quality is our basis for the realisation of your visions, your projects.

In our core sector, rotational moulding, we have been building years of solid knowledge since the early ‘60s, for your benefit in the optimisation of your specific project.

Design and application potentials in the field of mould constructions have changed due to the technological progress through the decades; new production techniques, materials etc. make requirements even more complex.

Our challenge is to keep pace with this progress.

Innovative techniques and future-oriented methods of resolution – always in close contact with our customers – are our key for it!

Read up upon our range of service – we will be pleased to advise you efficiently!

History

1925 |

Foundation as pattern making shop in Ettlingen |

1955 |

Development of a mould shop for aluminium moulds |

1962 |

Production of rotational moulds made of aluminium |

1970 |

HQ moved from Ettlingen to Karlsruhe, Grötzingen |

1987 |

Set up of an in-house aluminium foundry for own moulding applications, including the introduction of the „KELCH“ aluminium casting process |

1998 |

Adoption of CAD/CAM/CNC technology Founding member of the ARM-CE (Association of Rotational Moulders, Central Europe) |

2000 |

Development of own mould coatings (BMC - BlackMausCoat, today “C10“), which are the basis for the continuous creation of new types of coatings in the following years |

2001 |

Collaborative research as part of national and international research projects (EU projects: PlasCast, Micromelt, FastCast / BMBF projects: FLAME, PulForm / ZIM projects: Rotational moulding of concrete, generative filament winding) |

2003 |

Establishment of Maus Mould Services Ltd. (MMS Ltd.) based in Doncaster, UK |

2006 |

Production facility extended by 1,500 m², Investment in 5-axis HSC-machining centre, “Zimmermann FZ32 Compact“ (for the FastCast process) |

2008 |

Development of automation concepts (automatic spider) |

2010 |

First license for BMC - BlackMausCoat coating sold to Italy. In the following years further licenses to IN, TR, UK, USA |

2011 |

Continued expansion - new CAD/CAM workstations and process optimization in the area of CNC machining based on palletizing systems. Own R&D department, hire of development engineer in charge of collaborative research projects and product development (e.g. Rotocooler, Dropbox, Maus-O-Meter) |

2012 |

Introduction of CAD/CAM system "Siemens-NX" Investment in a scan camera for digitization and reverse engineering |

2015 |

Investment in a HSC-machining centre, "Zimmermann FZ33 Compact“ |

2016 |

Introduction of a special welding technology for the production of aluminium sheet moulds and aluminium hybrid moulds (cast-machined or sheet-aluminium) First automated injection moulds made of aluminium for the production of fibre-reinforced plastics (FRP) |

2017 |

Electrically heated rotational moulds for Robomoulds (automatic rotation production with robot arm) |

2018 |

Optimization of PPS System Webshop for mould accessories |

Key Figures

- 5.000m² Production area

- 70 Employees, incl. 7 apprentices

- 22 CAD/CAM workstations

- 8 CNC machining centres 6,000x3,000x1,500mm, 5-axis

- 8 Sand and shot peening cabins

- 4 Drying ovens 4,500x2,100x2,100mm

- 3 Melting furnaces with a total melt volume of 1,350 kg

- 1 Rotational moulding machine (lab facility)

- 94 Years of technical model construction

- 57 Years of manufacturing rotational moulding moulds

- 32 Years of in-house aluminium foundry

- 21 Years - Membership in the Association of Rotational Moulders in Central Europe (ARM-CE)

- 81 Apprentices since 1947

- 63 Years - Membership in the Modeller’s Association Baden

- 50 Exporting countries

- 5 Licensees for BMC coatings