We are constantly working on adapting the origin of our business, classic pattern making, to the latest technologies so we can provide you with a three-dimensional model. We normally start out with a given 3D CAD design, a drawing, a sketch, a sample, or we simply take over the construction of a 3D CAD design for you.

We bring our expertise and extensive experience to your ideas and create a finished product.

We advise you on the selection of a suitable manufacturing process, as well as on the appropriate material for your project.

These are some of the materials you may want to use:

- Wood (natural wood, glued laminated timber and plywood, chipboard)

- Metals (aluminium, brass, steel, stainless steel)

- Plastics (block, foam and plates)

- Resins (hard and flexible - epoxy, polyurethane, polyester, silicone)

- Plaster (model, pure gypsum and foamed plaster)

- Sand

- Clay

- Additional CNC-machinable materials

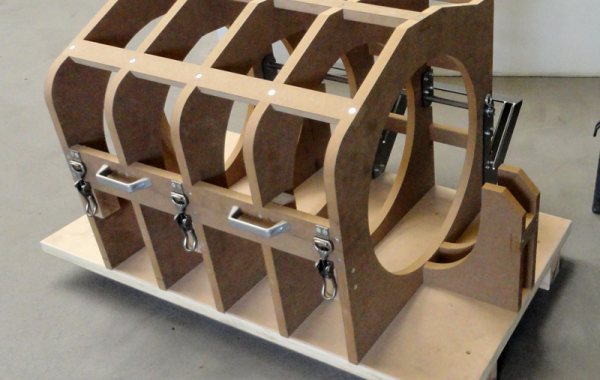

Due to our in-house production depth and the large variety of materials we use, we can offer you both maximum flexibility and best product quality.

Benefit from our innovative strengths!

- 1:1 Models

- Installation models

- Test and functional models

- Master patterns

- Plaster models for the ceramics industry

- Cooling and milling jigs

- Foaming jigs

- Foundry patterns

- Prototyping