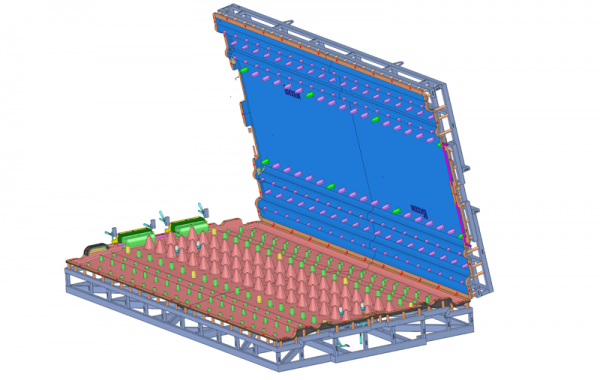

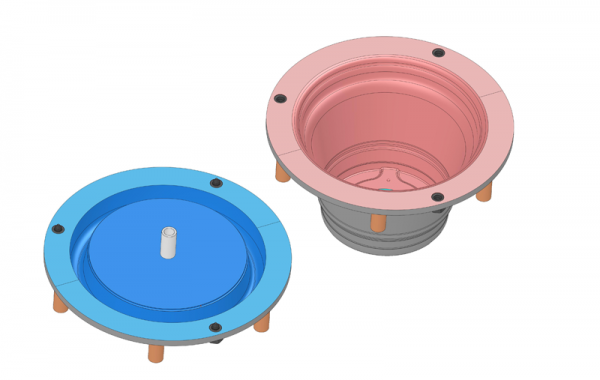

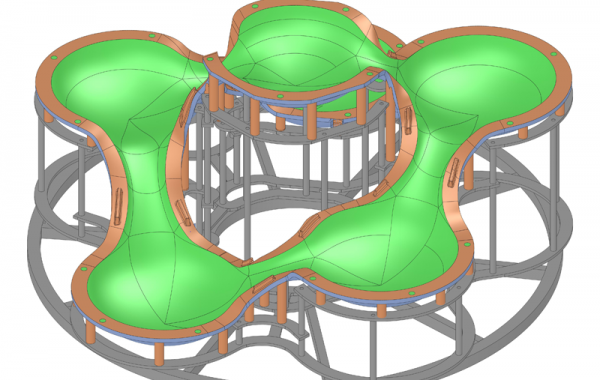

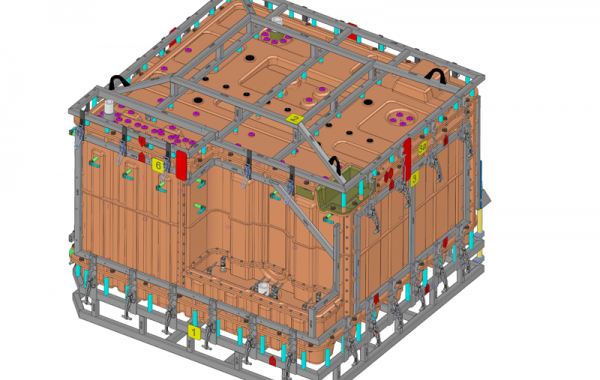

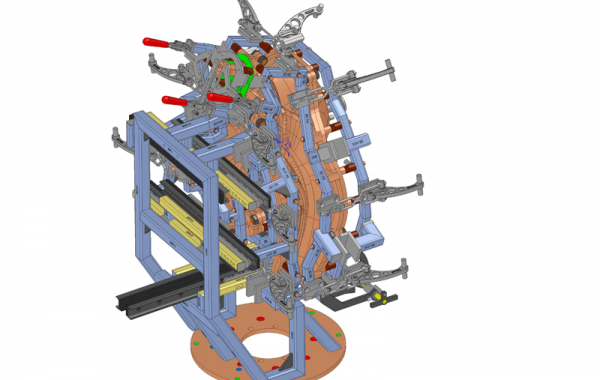

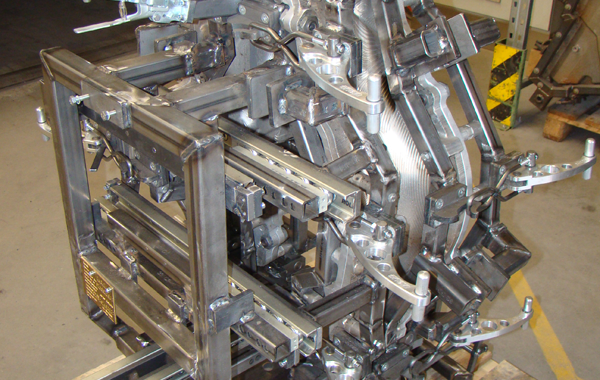

Using state-of-the art and process-optimized technology, we develop, design and manufacture rotational moulds for your individual projects. Needless to say that we meet your deadlines and quality standards. Based on your ideas and requirements, we select the ideal type of mould for your projects.

We stand for precise, innovative and sophisticated moulds of high quality and long life.

Benefit from our "full- service” and have us build your mould at our premises. We take care of all the required steps for you - from design to production - we provide full service out of one hand.

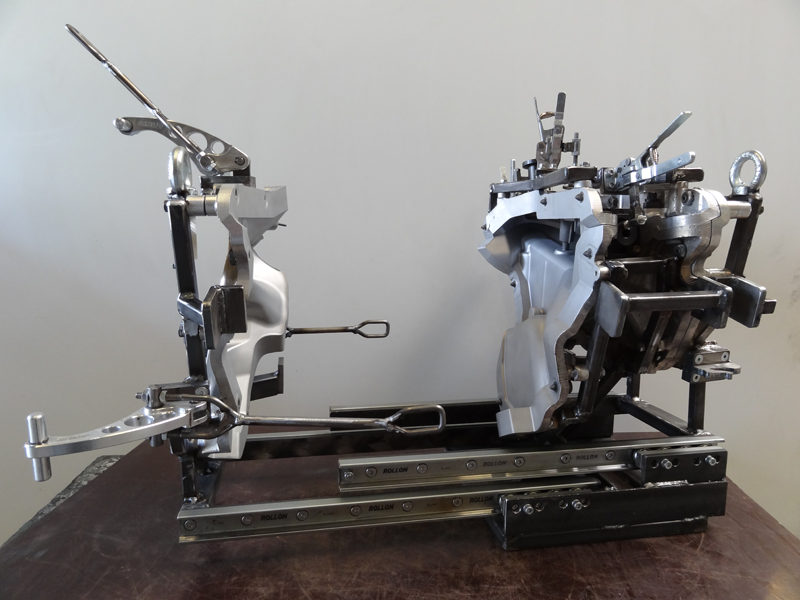

- CNC-machined aluminium moulds

- Cast aluminium moulds (FastCast + KELCH)

- Aluminium sheet moulds

- Hybrid moulds

- Lightweight moulds

- Prototype moulds

- Steel sheet moulds

- Galvano moulds