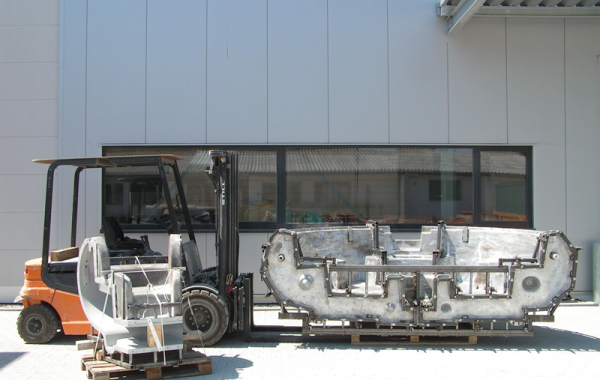

Our pattern and mould construction benefits from our internal aluminium foundry established 30 years ago. Regardless of the type of mould, we can thus offer casting tailored to your specific concept.

General key data on our aluminium foundry:

- From "very small" up to a size of 5,600 mm x 2,600 mm x 800mm

- Maximum casting volume of 1,350 kg

- 3 electrically heated tilting furnaces

- Dehumidified foundry

Based on our experience and the most diverse requirements, the department developed two separate special casting technologies.

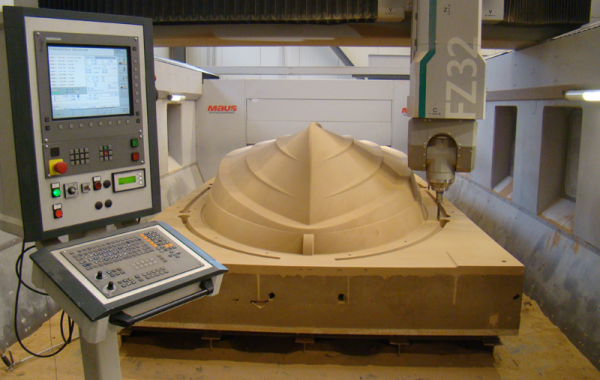

The FastCast process (FC) is a moulding and casting technique for thin-walled aluminium castings developed by Maus. Additional complex foundry patterns for casting aluminium moulds or prototypes are no longer required. The generative and immediate CNC machining of the moulded materials (sand/plaster/ceramic) enables us to produce aluminium castings of high precision and quality within no time at all.

Through the participation in various national and international research projects, we continually develop our casting technology. Take a look at the unbeatable advantages in countless applications and benefit from the results:

- Inserts (metal, graphite etc.)

- Water-soluble sandcores

- Digital, generative casting technology

- No storage of foundry patterns

- Resource-efficient

- Prototype casting

- Small series

- Vacuum casting

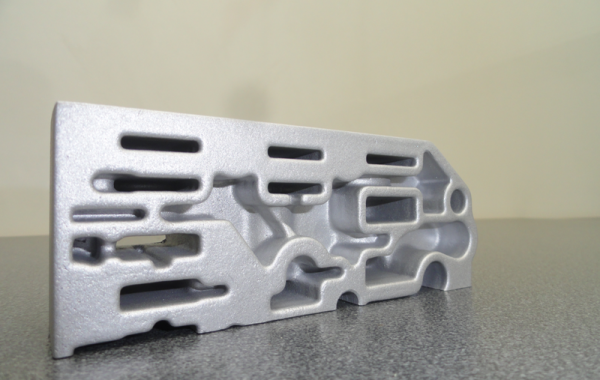

Since 1987, we have been using the KELCH process licensed from the US American company KELCH.

This unique technology allows us to mould and cast – without draft angles and with undercuts - the finest details and structures with maximum precision by using flexible models. Large, thin-walled aluminium castings can thus be produced easily.

Make your selection from our diverse range of structures:

- Stone structure

- Wood grain

- Terracotta design

- Textile structure

- Leather grain

- Floral ornaments

- Organic surfaces

- Design structures

- And many more

Virtually free porosity quality while ensuring a uniform thin wall casting is another advantage of this unique technique.